Brief History of Brickmaking in California

WASHINGTON BRICKS

History of Brickmaking in Washington

It is unknown exactly when the first kiln-fired brick was made in the State of Washington. Dilliplane (1981)

related that the first brick probably was made during the 1820s at Fort Vancouver. Fort Vancouver was established about

1825 by the Hudson's Bay Company for its western fur-trapping headquarters. According to Dilliplane, indications of

brickmaking at Fort Vancouver was in regards to the concerns of the Russian-American Company supplying its settlements

adequately with bricks. Prompted by a letter by Muraviev on September 3, 1824, the Russian-American Company authorized

one of its brickmakers to go to Fort Vancouver to learn how that Hudson's Bay Company post manufactured bricks.

Gurcke (1987) mentioned that the Hudson's Bay Company operated a soft-mud yard near Fort Vancouver, Clark County, on the

north side of the Columbia River some time before 1846. Also, an unnamed brickmaker at Hudson's Bay Company Fort Colville,

Stevens County, in 1841 made enough brick for two chimneys at the Tshimaka Mission, near the present site of Spokane.

Historian Bancroft (1890) reported that the first brick was made in July 1847, by Samuel Hancock and A. B. Rabbeson

on the farm of Simon Plomondon at Cowlitz Prairie, Lewis County. In 1854, Jack Quinnup and Bill Cooper built a

brick kiln just east of Grand Mound, Thurston County. In 1858, Marion F. Guess burned a kiln of bricks at Steilacoom,

Pierce County, but he could not compete with imported bricks. In 1859, Charles Plummer opened the first brickyard in

Seattle. In 1861, S. Meyer Clark opened at yard at San Juan Island. The scarcity of bricks set the price at $20 per

thousand.

Imported bricks were probably the reason for the slow or delayed development of Washington brick industry. Americans emigrated

to Washington in growing numbers beginning in the 1830s. The only bricks available to them were imported from outside of

the state. Many of the first brick structures and buildings in the state were constructed of imported brick. Early Washington

brickyards had a difficult time competing with bricks shipped here from Oregon, California, Boston, England, and elsewhere. Locally

made bricks were deemed inferior to the imported article. It wasn't until the 1880s when a large number of local brickyards

was established to supply the local demand and those yards were located in major cities.

Historian Durham (1912) published an interview with an experienced brickmaker from Napa, California, named J. T. Davie, who

went to Spokane, Washington, in 1880 to open a brickyard. Davie met another brickmaker named Roberts who had made bricks there

in the previous year but had failed due to their poor quality. Davie fired 30,000 bricks in his first kiln on Hangman Creek.

Davie's bricks were used in the first brick building, a warehouse, erected in Spokane in 1880. Many of

the first brick blocks in Spokane were also supplied by Davie's brickyard.

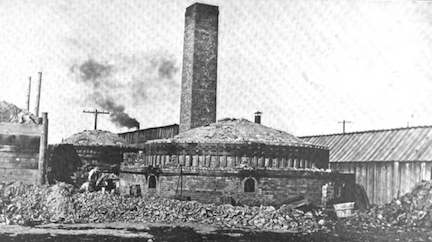

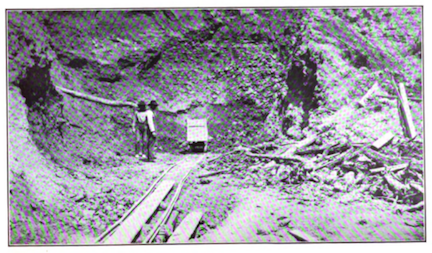

View of the Lohse clay bank, Seattle. From Shedd, 1910.

In 1870, the Steffen Brothers had established a brickyard in Seattle. By 1880, according to Bancroft (1890), Seattle, with

a population of 7,000, had three brickyards. Among them was J. C. McAllister, who had reopened Plummer's old yard in 1876

at the Dwamish River, and Frazier and Moon, who opened a yard at Lake Union. In 1881, Carmi Dibble opened a brickyard.

By 1882, McAllister was the largest manufacturer of bricks in Seattle.

Other early brickyards were established throughout Washington. At East Olympia, or Swantown, Billings and Mason was operating

a brickyard in 1870. At Olympia, William Billings opened a yard in 1880. In 1881, H. Z. Burkhart burned a kiln of 80,000

bricks at Bellevue and Charles Careau and Company opened a yard at Cheney. Sing Lee and Company had the first Chinese brickyard

at Tacoma in 1884. Gill Brothers and Charles A. Enell also opened brickyards at Tacoma that year. By the 1890, nearly every

city in Washington had at least one brickyard.

The first recorded brick company was established at Tacoma in 1884 by the Fox Island Brick Manufacturing Company. This was

followed by the Seattle Brick and Tile Company at Seattle in 1887. The devastating fire of 1889 at Seattle spawned the opening of

many new brickyards as demand exploded for fireproof building material. Denny Clay Company of Seattle became a major producer

of clay products. Other companies soon followed including the Puget Sound Brick, Tile and Terra Cotta Company, Pontiac Brick

Company, and Ranke and Lohse Company. At Spokane, the Washington Brick and Lime Company was established in 1889, followed by

the Spokane Brick Company, and others. In 1901, the Renton Clay Company opened at Renton.

Most of these early Washington brickyards manufactured red common building bricks. These bricks were made from the surface

deposits of clay loam or sandy loam that was commonly found near the building sites. The red-burning clay was mined from pits or

quarries. It soon became apparent that Washington also contained higher quality clays for the manufacture of pressed face brick,

vitrified paving brick, and refractory firebrick. These higher grade clays were found in shale deposits or were formed from the

decomposition of granitic or volcanic rocks. Higher grade clays were mined from surface quarries or underground mines. It was

desirable to build the brick plant near the clay bank to reduce the transporting cost.

The first company to make glazed face brick in the state was the Steffen Brothers at Seattle in the 1870s for the fronts

of buildings. The Denny Clay Company was credited as being the first to manufacture vitrified paving brick at its plant at

Van Asselt, located four miles south of Seattle, in 1893. The shale used for making paving brick came from its

Taylor clay mine. Spokane purchased 5 million paving bricks for its streets in 1897. Denny-Renton paving bricks were said

to be the best made on the Pacific Coast. The first firebricks in the state were made in 1893 by the Washington Brick and Lime

Company at its Clayton plant and by Oudin and Bergman of Spokane. Denny Clay Company immediately followed with its firebricks in 1894 from

its Taylor mine for the Tacoma smelter. Since 1887, all of these companies also made fine pressed face bricks along with

ornamental shapes for beautifying the fronts of buildings.

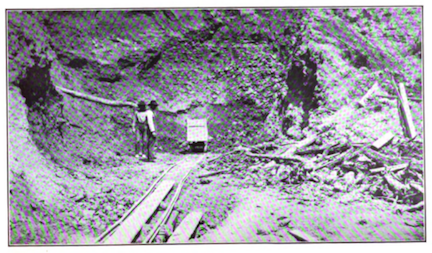

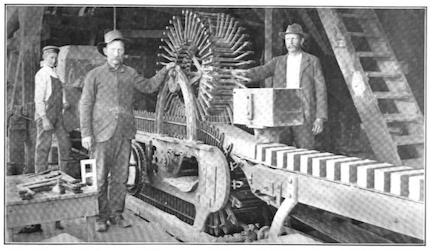

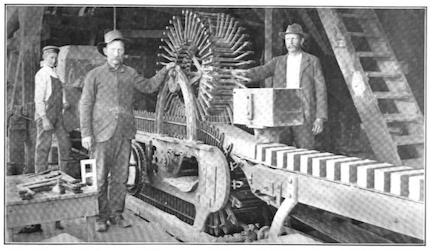

View of the brick machine at the Abrahamson brickyard, Seattle. From Shedd, 1910.

The first brick manufacturing machine was reported in 1887 for J. T. Davie at Spokane. Davie made 3 million bricks with the new

machine. It was not specified what type of brick machine Davie got, but most likely it was some kind of soft-mud machine. Also in

1887, Washington Brick and Lime Company acquired a brick machine that made 20,000 bricks per day and one that made pressed

brick. In 1889, Builders Material Company of Seattle acquired a dry press brick machine from St. Louis. In 1892, Sherman

and Wasson of Everett had the state's first reported stiff-mud brick machine that made wire-cut bricks. By 1910, according

to Gurcke (1987), 5 brickyards had soft-mud machines, 6 yards had dry press machines, 34 yards had stiff-mud machines, and 18 yards

had repress machines.

These early clay companies were located on major railroads or railroad spur lines. The yards in the vicinity of Seattle and

Tacoma had port access. By 1900, Washington bricks found an expanding market beyond the stateline. Bricks, especially its

paving bricks, were shipped throughout Western states and as far away as Alaska, British Columbia, and South Africa.

The 20th century saw the closing or consolidation of smaller brickyards due to competition. Larger brick companies bought out

the smaller or less successful companies. In 1893, the Puget Sound Brick, Tile and Terra Cotta Company was purchased by the Denny

Clay Company. In 1905, Denny Clay Company joined with the Renton Clay Company to form the Denny Renton Clay and Coal Company.

Denny Renton employed nearly 1,000 workers and controlled four plants following that merger. In 1904, Oudin and Bergman of

Spokane became the American Fire Brick Company, which had its yard at Mica. In 1913, the Little Falls Fire

Clay Company at Little Falls was purchased by the Standard Clay Company. Washington produced about 50 million building bricks

per year, valued at $1 million per year, and 3 million firebricks per year, valued at $100,000 per year. By 1901, Spokane

firebricks were selling at $50 per thousand and successfully competing with Scottish firebricks selling at $60 per thousand.

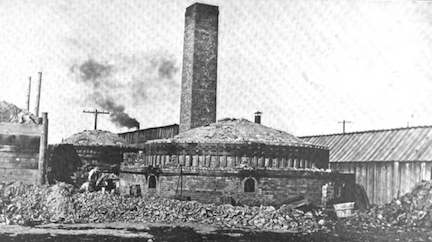

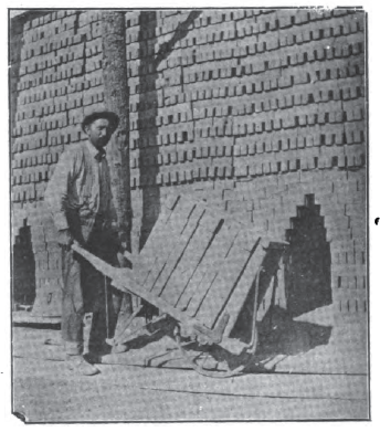

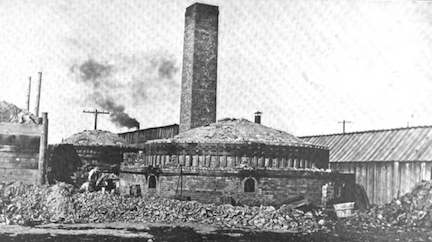

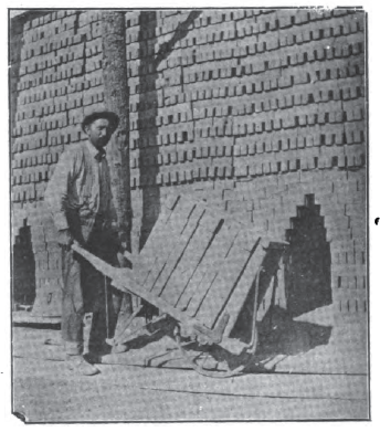

Brick cart and brick kiln. From Brick, 1902.

During the 1920s, demand for paving brick declined when automobile traffic increased and asphalt became the preferred road

paving material. Demand for other clay products also declined when concrete replaced brick and terra cotta wall tile in

structural building materials. Building bricks had been declining steadily since 1910. Firebricks, on the other hand, were

increasing in demand. This was the reason Gladding, McBean and Company, a California-based company, in 1927 purchased the

Denny-Renton Clay and Coal Company and turned the Renton plant into a firebrick maker. Gladding, McBean and Company also

acquired the American Fire Brick Company at Mica in 1929 and the Washington Brick and Lime Company at Spokane in 1957.

In 1962, Gladding, McBean and Company merged with Lock Joint Pipe Company of New Jersey to form the International Pipe and

Ceramics Corporation, which continued manufacturing firebrick into the 1980s. The Mica plant was sold to Mutual Materials

in 1990.

The Hidden Brick Company of Vancouver opened in 1871 making sand-molded common bricks and this company was the last to make

such bricks until it closed in 1992. The Builders Brick Company opened in Seattle in 1900 and in 1960 acquired Mutual Materials.

In 1966, Builders Brick Company changed its name to Mutual Materials and expanded its operations throughout the Pacific Northwest,

with yards or offices in Washington, Oregon, Idaho, Montana, and Western Canada, and with over 400 employees. This company made

stiff-mud bricks in both solid and cored forms and in a variety of colors and textures. In 2011, Mutual Materials closed one

of its plants at Newcastle, but continued operations at its Mica plant. In 2014, Real Thin Brick opened in Seattle to

manufacture thin veneer brick. These are the only brick manufacturing companies currently operating in Washington.

View of a pallet of brick at the Hidden Brick Company yard. Photo courtesy of Karl Gurcke.

References

Bagley, Clarence B., History of Seattle From the Earliest Settlement to the Present Time, v. 2 The S. J. Clarke

Publishing Company, 1916.

Bancroft Hubert Howe, The Works of Hubert Howe Bancroft, v. 31, History of Washington, Idaho, and Montana, 1845-1889

The History Company, Publishers, San Francisco, 1890.

Brick, v. 16, no. 5, May 1902, p. 237.

College of Mines, The College of Mines Series of Ores, Coals and Useful Rocks of Washington,

Bulletin of the University of Washington, University Extension Series No. 21, General Series No. 110, Seattle, April 1917.

Dilliplane, Timothy L., Brickmaking In Russian America: Research Results Through March 18, 1981, Fort Ross Conservancy

Library, Heritage, monthly newsletter of the Alaska Office of History and Archaeology, No. 4, January, 1983.

Durham, Nelson W., History of the City of Spokane and Spokane Country, Washington: From Its Earliest Settlement to the

Presen Time, Volume 1, S. J. Clarke Publishing Company, 1912.

Gurcke, Karl, Bricks and Brickmaking, A Handbook for Historical Archaeology, The University of Idaho Press, Moscow,

Idaho, 1987.

Gurcke, Karl, written communications, 2017.

Hilding, Tina, Renton history built with bricks, Black Diamond History, accessed 3 November 2017,

https://blackdiamondhistory.wordpress.com/2017/08/26/renton-history-built-with-bricks/.

Matsumura, JoAnne, written communications, 2017.

Mutual Materials, www.mutualmaterials.com, accessed 22 December 2017.

Mutual Materials' Newcastle brick plant site up for sale, Bizjournals.com, accessed 22 December 2017.

Nisbet, Jack and Claire, Hudson's Bay Company, HistoryLink.org Essay 9881, https://www.historylink.org/File/9881

(accessed 24 January 2020).

Patty, Ernest N. and Glover, Sheldon L., The Mineral Resources of Washington With Statistics for 1919, Washington

Geological Survey Bulletin no. 21, Olympia, 1921.

Prosser, William F., A History of The Puget Sound Country, v. 1 The Lewis Publishing Company, 1903.

Real Thin Brick, www.realthinbrick.com, accessed 3 March 2020.

Shedd, Solon, The Clays of the State of Washington, State College of Washington, Pullman, Washington,

June 1910.

Warren James, Paving the way: King County bricks built roads around the world, Seattle Post-Intelligencer, accessed 4 November 2017,

https//blackdiamondhistory.wordpress.com/2014/12/07/paving-the-way-king-county-bricks-built-roads-around-the-world/.

Copyright © 2020 Dan L. Mosier